Flanged Fittings is the traditional finger-tight fittings for connecting Teflon tubing and performs well in high pressure up to 1.5Mpa non-movable systems, the advantage is that tubing end will not be deformed to cause fluid leakage or less, the disadvantage is that professional flange tools are required every time when tubing needs to be replaced.

Model No. | Material | Color | Thread | Pressure Rating (psi/Mpa) | Tubing OD |

F702-1/4-28P | PP | Natural PP/PTFE | 1/4-28UNF | ≥ 217.5/1.5 | 1.6/2.0mm |

F702-1/4-28E | PTFE | ||||

F802-1/4-28P | PP | 2.5/3.0/3.175/3.2mm | |||

F802-1/4-28E | PTFE | ||||

F702-M6P | PP | M6 | 1.6/2.0mm | ||

F702-M6E | PTFE | ||||

F802-M6P | PP | 2.5/3.0/3.175/3.2mm | |||

F802-M6E | PTFE |

*If the outer diameter of your teflon tube is 4.0mm, please contact us about how to order the right model.

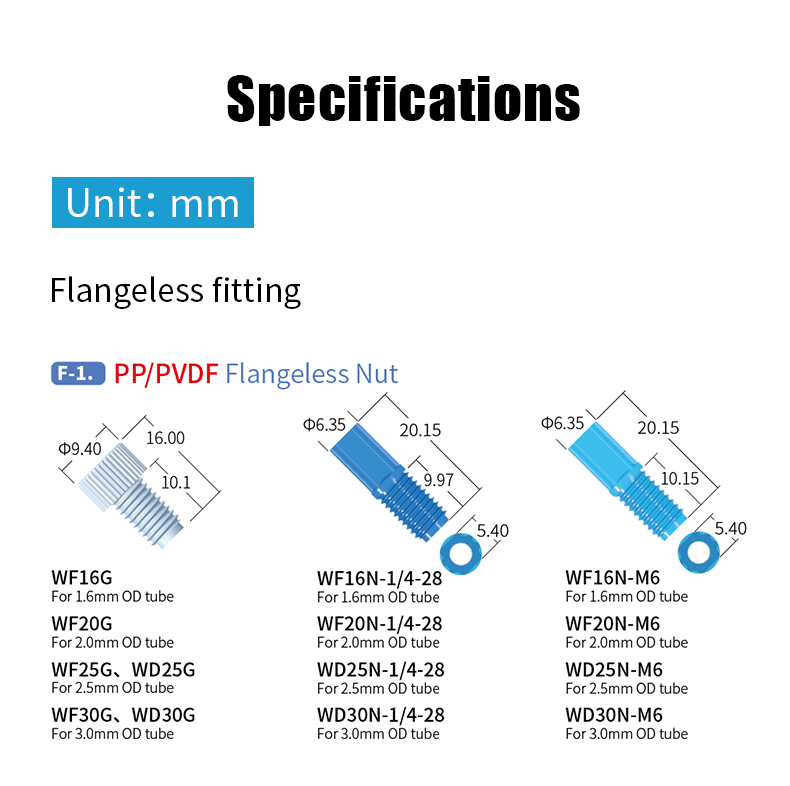

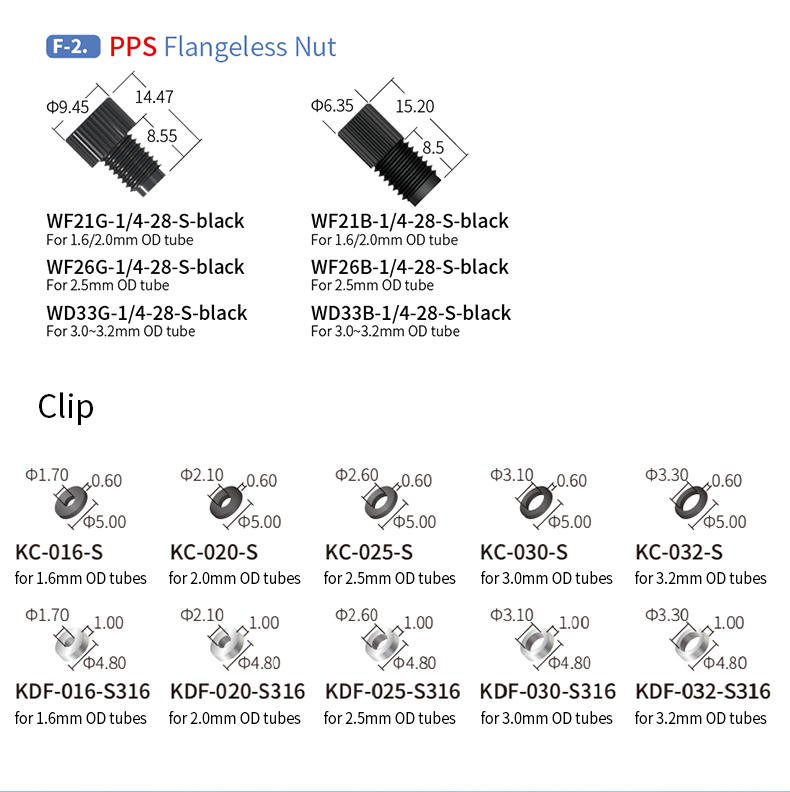

Dimension (unit: mm)

1. Choose 1/4-28 nut when receiving port is 1/4-28; Choose M6 nut when receiving port is M6.

2. Before flange the tubing, ensure the end of the tubing has a clean, square, burr-free cut. This is very important, as the square cut helps the tubing make full contact with the bottom of the mating port. Neglecting to properly cut the tubing could lead to dead volume, resulting in peak distortion such as fronting, tailing or broadening.

3. Two-Piece Fittings Installation Steps:

a. Flange the tubing end with exclusive flange tool

b. Slide the nut, insert the assembly into the receiving port, pushing the tubing into the port until it bottoms out.

c. Finger tighten the nut into the port until snug.